Introduction

The ceramic honeycomb ozone-removing filter, a breakthrough in air and gas purification, combines advanced material science with catalytic chemistry to address ozone pollution efficiently. By leveraging a manganese oxide-based catalyst embedded in a porous ceramic honeycomb structure, this technology converts harmful ozone (O₃) into breathable oxygen (O₂) at room temperature, with zero energy consumption. This article explores its scientific principles, material innovations, industrial applications, and future potential, positioning it as a critical solution for industries ranging from healthcare to wastewater management.

1. Scientific Principles: How Ozone Decomposition Works

Catalytic Mechanism

The core of the filter lies in its manganese oxide (MnOx) catalyst, which accelerates the decomposition of ozone through a redox reaction:

2O₃ → 3O₂

The process occurs in three stages:

- Adsorption: Ozone molecules adhere to the catalyst’s active sites on the ceramic surface.

- Dissociation: MnOx reduces the activation energy required to break O₃’s unstable bonds, splitting it into O₂ and atomic oxygen (O).

- Recombination: Atomic oxygen combines with another O₃ molecule or O₂ to form stable oxygen.

This reaction is 100% energy-efficient, requiring no heat, light, or external power—a stark advantage over UV-based or plasma ozone destructors.

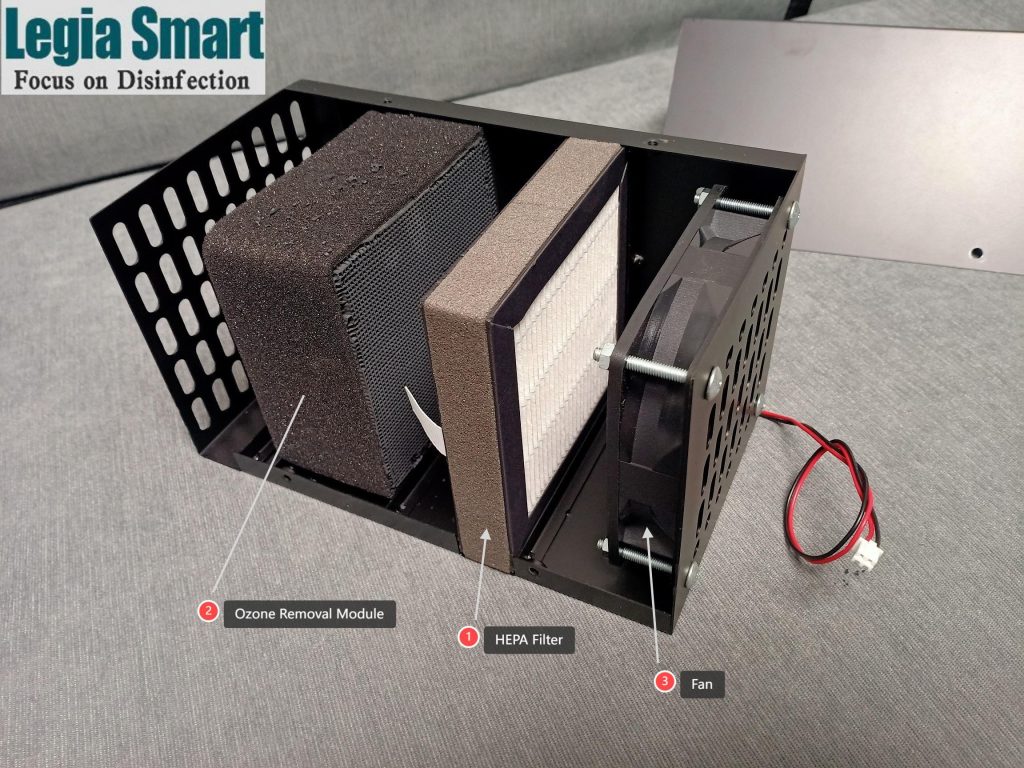

Role of the Ceramic Honeycomb Structure

The ceramic honeycomb acts as both a catalyst carrier and a structural enhancer:

- High Surface Area: With 150 cells per square inch, the honeycomb design maximizes contact between ozone and the catalyst.

- Low Pressure Drop: Thin walls (100×100×50mm) ensure minimal airflow resistance (<2.0 m/s), critical for HVAC systems.

- Thermal Stability: Alumina-silica ceramics withstand temperatures up to 800°C, preventing degradation in high-heat environments.

2. Material Science: Innovations Behind the Filter

Catalyst Composition

The manganese-based composite metal oxide is engineered for longevity and reactivity:

- Doping with Transition Metals: Cobalt or iron additives enhance electron transfer efficiency, boosting decomposition rates.

- Nanostructured Coatings: Nano-sized MnOx particles (10–50nm) increase active sites, achieving ≥95% efficiency even at high flow rates.

Carrier Material: Modified Porous Activated Carbon

The ceramic honeycomb is coated with activated carbon (≥1500m²/g surface area), which:

- Traps volatile organic compounds (VOCs) and particulate matter, preventing catalyst poisoning.

- Enhances ozone adsorption via π-π interactions between carbon’s graphene layers and O₃ molecules.

Durability Enhancements

- Corrosion Resistance: A zirconia (ZrO₂) coating protects the ceramic from acidic byproducts in industrial exhaust.

- Hydrophobic Treatment: Silane-modified surfaces repel moisture, maintaining catalytic activity in humid environments.

3. Industrial Applications and Case Studies

Air Purification Systems

- UV Printers & Laser Equipment: A semiconductor factory reduced workplace ozone levels from 0.2 ppm to <0.01 ppm using these filters, complying with OSHA’s 0.1 ppm PEL limit.

- Medical Sterilization: Hospitals integrate the filters into post-sterilization ventilation, eliminating residual ozone from autoclaves without energy costs.

Wastewater Treatment

- Ozone Tail Gas Management: In a municipal plant, ceramic filters achieved 99% ozone conversion in ozonation systems, preventing ground-level ozone formation.

High-Voltage Equipment

- Plasma Generators: A study showed 98% ozone removal in plasma-based air purifiers, addressing secondary pollution from ionizers.

4. Technological Advancements and Future Trends

AI-Optimized Filter Design

Machine learning models now predict optimal honeycomb density and catalyst loading based on airflow patterns, improving efficiency by 15–20%.

Green Manufacturing

- Recyclable Ceramics: Emerging techniques use 30% recycled industrial ceramics, reducing production carbon footprints.

- Biodegradable Binders: Plant-based binders replace traditional polymers, aligning with circular economy goals.

Integration with IoT

Smart filters equipped with real-time ozone sensors and wireless alerts are entering the market, enabling predictive maintenance and data-driven air quality management.

5. Comparative Advantages Over Traditional Methods

| Method | Energy Use | Efficiency | Lifespan | Cost |

|---|---|---|---|---|

| Ceramic Honeycomb Filter | Zero | 95–99% | 10,000+ hrs | Moderate (long-term savings) |

| UV Ozone Destructors | High | 70–85% | 5,000 hrs | High (bulb replacement) |

| Thermal Destruction | Very High | 90–95% | 2,000 hrs | Very High |

6. Installation and Maintenance Best Practices

Installation Guidelines

- Orientation: Ensure the filter is perpendicular to airflow to maximize contact time.

- Sealing: Use silicone gaskets to prevent bypass leakage, which can reduce efficiency by 30–40%.

Maintenance Tips

- Cleaning: Blow compressed air (≤0.3 MPa) every 6 months to remove dust buildup.

- Replacement: Monitor pressure drops; a 15% increase signals clogging.

7. Challenges and Solutions

Catalyst Deactivation

- Cause: Sulfur compounds or heavy metals in industrial exhaust can poison MnOx.

- Solution: Pre-filters with activated carbon beds absorb contaminants before they reach the catalyst.

High Humidity

- Cause: Water molecules block active sites.

- Solution: Hydrophobic coatings or pre-dehumidifiers maintain performance.

Conclusion

The ceramic honeycomb ozone-removing filter represents a fusion of material innovation and catalytic science, offering a sustainable, cost-effective solution for ozone pollution. With advancements in AI-driven design, recyclable materials, and IoT integration, it is poised to dominate industries seeking compliance with stringent air quality regulations. As urbanization and industrial activities escalate, this technology will play a pivotal role in safeguarding environmental and human health—proving that cutting-edge science can align with ecological responsibility.

Keywords:

Ceramic honeycomb ozone filter;Manganese oxide catalyst ozone removal;Zero energy ozone decomposition;High-efficiency ozone filter;Ozone pollution control;Ceramic catalyst air purification;Ozone to oxygen conversion;Industrial ozone removal solutions;Activated carbon ozone filter;HVAC ozone treatment;Medical sterilization ozone removal;Wastewater ozone tail gas;Plasma-generated ozone treatment;Durable ceramic catalyst;Low-pressure drop ozone filter;Ozone decomposition mechanism;Nanostructured manganese oxide;Sustainable ozone removal technology;IoT-enabled ozone filters;Corrosion-resistant ceramic honeycomb