UV Sterilization Technology: A Powerful Tool for Safe, Efficient Disinfection

UV (Ultraviolet) sterilization technology has become one of the most reliable and widely used methods for disinfecting air, water, and surfaces across various industries. From healthcare settings to food production, UV sterilization offers a chemical-free, fast, and efficient way to eliminate harmful microorganisms and pathogens. In this article, we explore how UV sterilization works, its applications, advantages, limitations, and the science behind its effectiveness.

Understanding UV Sterilization

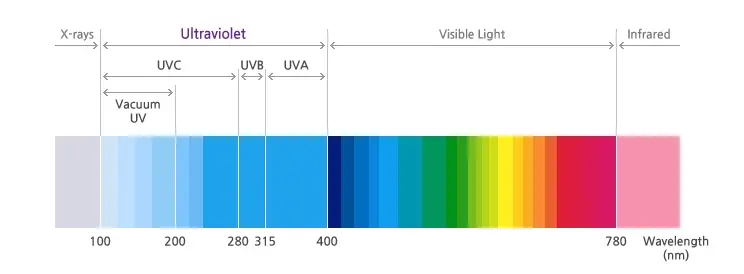

UV sterilization involves the use of ultraviolet light, a type of electromagnetic radiation, to destroy or inactivate microorganisms like bacteria, viruses, fungi, and protozoa. UV light exists in the electromagnetic spectrum beyond visible light and is divided into three main types based on wavelength: UVA, UVB, and UVC.

- UVA (320–400 nm): Long-wave UV radiation, not typically used for sterilization.

- UVB (280–320 nm): Medium-wave UV radiation, harmful to living organisms but not primarily used for disinfection.

- UVC (200–280 nm): Short-wave UV radiation, most effective for sterilization purposes.

UVC is the key wavelength used in sterilization because of its ability to break down the DNA or RNA of microorganisms, rendering them unable to replicate and causing their eventual death. This process is known as photodimerization, where UV-C light disrupts the molecular bonds in the DNA, preventing reproduction.

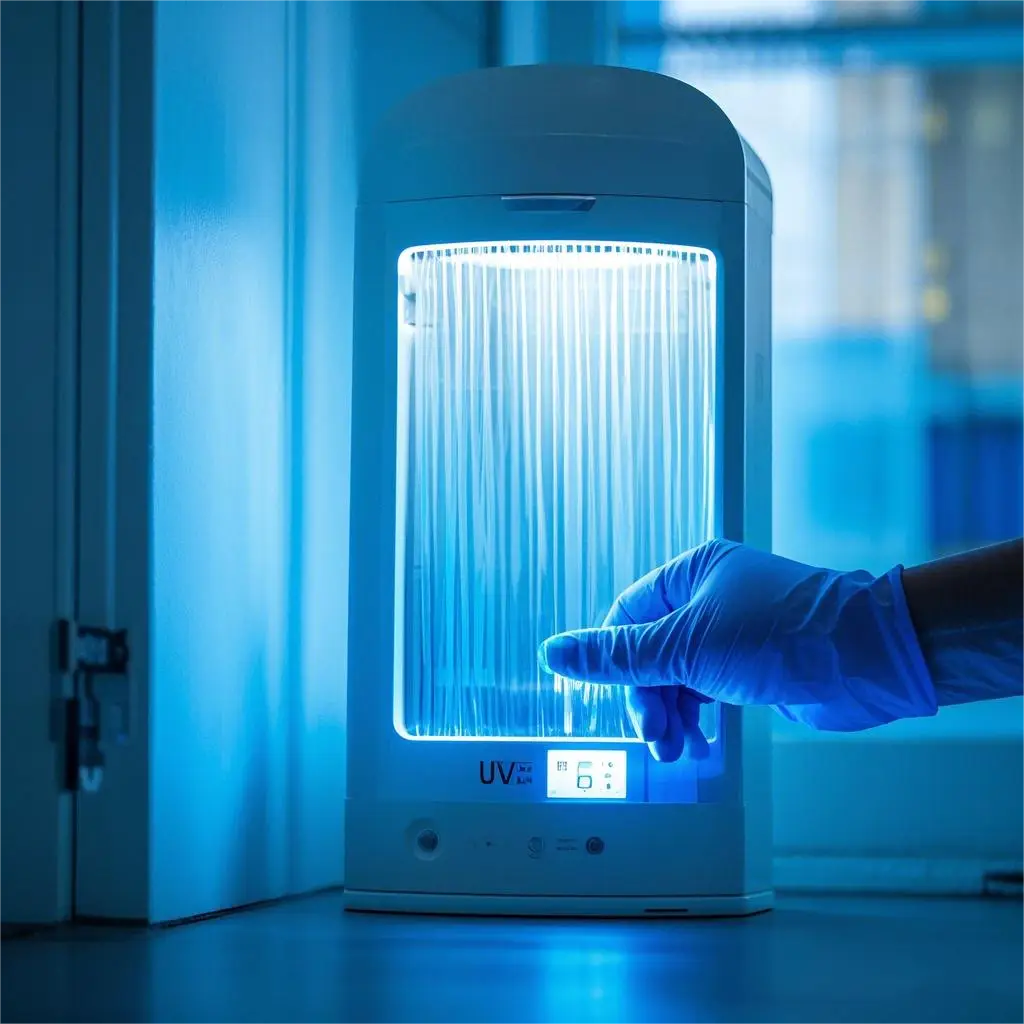

How UV Sterilization Works

UV sterilization works by emitting UV-C light, typically from a mercury vapor lamp or LED source, onto the surface, water, or air that needs to be disinfected. The pathogens exposed to UV-C light absorb the radiation, leading to the formation of thymine dimers in their DNA. These dimers cause mutations that prevent the microorganism from replicating, thereby neutralizing the threat. The effectiveness of UV sterilization depends on several factors:

- Intensity of UV-C light: Stronger UV-C light results in faster and more effective disinfection.

- Exposure time: The longer a microorganism is exposed to UV-C light, the more likely it is to be inactivated.

- Distance from the UV source: The closer the microorganism is to the UV source, the more effective the sterilization.

- Wavelength: UVC light in the range of 260–270 nm is the most effective for sterilization.

Applications of UV Sterilization

UV sterilization has widespread applications across many sectors. Below are some of the key industries benefiting from this technology:

- Healthcare and Medical Facilities

- Disinfection of Surfaces: UV light is used to disinfect patient rooms, operating theaters, and other areas in hospitals to eliminate harmful pathogens.

- Sterilization of Equipment: Medical instruments, particularly those that cannot be exposed to heat or chemicals, can be disinfected with UV-C light.

- Air Disinfection: UV air purifiers are used in hospitals to sterilize air in high-risk areas, such as surgical rooms and intensive care units (ICUs), preventing airborne transmission of infectious diseases.

- Water Treatment

- UV-C light is widely used in water purification systems for residential, commercial, and industrial purposes. It is effective in neutralizing harmful microorganisms in drinking water, wastewater treatment plants, and recreational water facilities, like swimming pools and spas, without the use of chemicals.

- Food and Beverage Industry

- UV-C sterilization is used to sanitize food processing equipment, surfaces, and even food products (such as fruits and vegetables) to prevent contamination from harmful bacteria and pathogens. It is also used for purifying liquids like juices and dairy products.

- HVAC Systems

- UV-C lamps are used to disinfect air circulating through HVAC systems. This prevents the growth of mold, bacteria, and viruses, improving air quality in offices, homes, and commercial buildings.

- Consumer Products

- Many consumer products, such as UV sterilizers for phones, toothbrushes, and small kitchen appliances, utilize UV-C technology for convenient, on-demand disinfection.

- Pharmaceuticals and Biotechnology

- UV-C sterilization is applied in laboratories and cleanrooms to maintain sterile environments. It is used to disinfect surfaces, tools, and equipment critical in the production of pharmaceuticals and biotechnological products.

Advantages of UV Sterilization

UV sterilization offers a range of advantages, making it a popular choice in various industries:

- Chemical-Free: Unlike traditional disinfectants, UV sterilization does not require chemicals or additives, making it an environmentally friendly option. It also eliminates the potential health risks associated with chemical residues.

- Speed and Efficiency: UV disinfection works quickly, with many systems capable of sterilizing surfaces or air in minutes. This makes it ideal for high-turnover areas like hospitals, kitchens, or public spaces.

- Broad-Spectrum Effectiveness: UV-C light is effective against a wide range of pathogens, including bacteria, viruses, mold, and algae. It can inactivate microorganisms that are resistant to traditional disinfectants.

- Cost-Effective: Once installed, UV sterilization systems are relatively low-maintenance and energy-efficient, with a long service life for the UV-C lamps. It reduces the need for disposable sterilizing agents.

- No Residuals: UV light does not leave behind harmful residues or by-products, ensuring a clean and safe environment for people and products.

Limitations of UV Sterilization

While UV sterilization is highly effective, it does have limitations:

- Line-of-Sight Requirement: UV-C light only disinfects the areas it directly reaches, so surfaces hidden from direct light (like the underside of objects) may not be sterilized.

- Effectiveness Depends on Intensity: The effectiveness of UV sterilization is heavily dependent on the intensity of the light and the exposure time. A lower intensity or short exposure time may result in insufficient disinfection.

- Safety Concerns: UV-C light can be harmful to human skin and eyes. Therefore, UV sterilization systems are usually designed to operate in unoccupied areas or with safety measures to protect users from direct exposure.

- Maintenance: UV-C lamps degrade over time and need periodic replacement to maintain their effectiveness. Some systems also require regular cleaning of lamps and reflectors to ensure maximum efficiency.

- Energy Consumption: Although energy-efficient, UV sterilization systems still require electricity to operate, which can be a consideration in large-scale or continuous applications.

Conclusion

UV sterilization technology is a powerful, chemical-free, and fast method for eliminating harmful microorganisms. Its broad-spectrum effectiveness, coupled with its safety and ease of use, makes it an attractive solution for a variety of industries, including healthcare, water treatment, food safety, and air purification. However, it is important to consider its limitations, such as line-of-sight requirements and safety concerns, when designing and using UV disinfection systems. With proper application and maintenance, UV sterilization can significantly enhance hygiene and safety standards across various sectors.

By incorporating UV sterilization into disinfection protocols, industries can ensure a safer, more sustainable approach to controlling harmful pathogens, improving public health, and promoting environmental sustainability.