Introduction

In an era where microbial resistance and environmental sustainability are critical concerns, photocatalytic disinfection has emerged as a cutting-edge technology for eliminating pathogens across industries. Leveraging the power of light-activated catalysts, this method offers a chemical-free, energy-efficient, and long-lasting solution for medical, industrial, and environmental sterilization. This article explores the science, applications, and innovations behind photocatalytic disinfection systems, positioning them as a cornerstone of modern hygiene practices.

1. The Science of Photocatalytic Disinfection

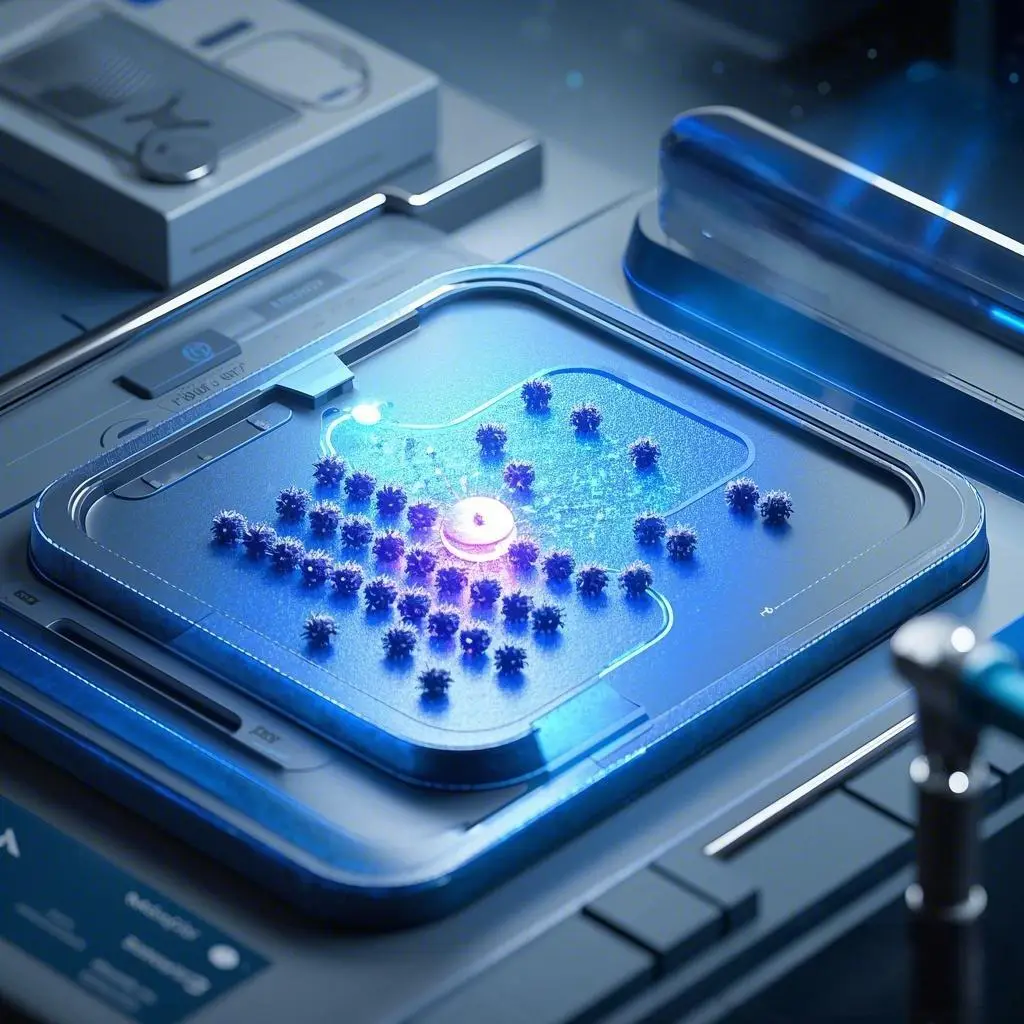

Photocatalytic disinfection relies on light-activated semiconductors, primarily titanium dioxide (TiO₂), to generate reactive oxygen species (ROS) that degrade organic pollutants and destroy microorganisms. The process involves three key steps:

- Photoactivation: When TiO₂ nanoparticles are exposed to ultraviolet (UV) or visible light, electrons are excited from the valence band to the conduction band, creating electron-hole pairs.

- ROS Generation: These pairs react with water and oxygen to produce hydroxyl radicals (•OH) and superoxide ions (O₂⁻), which are highly oxidative.

- Pathogen Destruction: ROS rupture microbial cell membranes, oxidize proteins, and damage DNA/RNA, achieving up to 6-log reduction in bacteria, viruses, and fungi.

Key Advantages:

- Broad-Spectrum Efficacy: Effective against antibiotic-resistant bacteria (e.g., MRSA), enveloped viruses (e.g., SARS-CoV-2), and spores.

- Zero Chemical Residues: Ideal for sensitive environments like neonatal wards or food processing.

- Continuous Action: Works under ambient light, ensuring 24/7 disinfection.

2. Industrial Applications of Photocatalytic Technology

Healthcare & Medical Facilities

- Surface Sterilization: TiO₂-coated walls, beds, and equipment in ICUs reduce HAIs by 70% (per CDC studies).

- Air Purification: HVAC-integrated photocatalytic filters neutralize airborne pathogens like Aspergillus.

Food & Beverage Production

- Packaging Sterilization: UV-activated photocatalytic films on food containers inhibit E. coli and Salmonella.

- Water Treatment: TiO₂ reactors degrade biofilms in pipelines without chlorine.

Environmental Remediation

- Wastewater Disinfection: Solar-driven photocatalytic systems break down pharmaceutical residues and Legionella in municipal water.

- Public Spaces: Self-cleaning photocatalytic coatings on subway handles or elevator buttons reduce cross-contamination.

Industrial Manufacturing

- Cleanroom Safety: Photocatalytic air scrubbers maintain ISO Class 5 standards in semiconductor production.

3. Technological Innovations Enhancing Performance

Modern photocatalytic systems integrate advanced engineering to overcome traditional limitations:

- Visible-Light Activation: Nitrogen-doped TiO₂ (N-TiO₂) enables catalysis under indoor lighting, reducing UV dependency.

- Nano-Engineered Coatings: Mesoporous TiO₂ structures increase surface area by 300%, enhancing ROS yield.

- Hybrid Systems: Combining TiO₂ with silver nanoparticles or graphene oxide amplifies antimicrobial efficiency.

- IoT Integration: Smart sensors monitor ROS levels and automatically adjust light intensity for optimal disinfection.

Case Study: A European hospital reduced surface contamination by 90% using TiO₂-coated curtains activated by ambient LED lighting.

4. Designing Effective Photocatalytic Disinfection Systems

Selecting the right system requires evaluating:

- Substrate Compatibility: TiO₂ coatings adhere to glass, ceramics, and polymers but require pretreatment for metals.

- Light Source Optimization: UV-A (365 nm) LEDs vs. visible light panels, depending on application.

- Durability: Coatings must withstand abrasion, humidity, and repeated cleaning cycles.

- Certifications: Compliance with ISO 27447 (photocatalytic antibacterial testing) or NSF/ANSI 50 (water treatment).

Recommended Systems:

- Medical Grade: Wall-mounted photocatalytic air purifiers with HEPA + TiO₂ filters.

- Industrial Grade: Centralized UV-TiO₂ reactors for water or air disinfection at scale.

Conclusion

Photocatalytic disinfection represents a paradigm shift in sterilization technology, combining sustainability with uncompromising efficacy. By harnessing light-driven reactions, industries can achieve continuous, chemical-free pathogen control while meeting stringent regulatory standards.

As pioneers in photocatalytic solutions, we engineer systems tailored to your operational needs—from hospital-grade coatings to industrial-scale reactors. Contact us to explore how this technology can redefine your disinfection strategy.

Focus Keywords:

Photocatalytic disinfection, TiO2 sterilization technology, UV-activated disinfection, antimicrobial coatings, sustainable sterilization solutions.

References:

- Title: “Advanced Oxidation Processes for Water Disinfection: Mechanisms and Applications”

Journal: Environmental Science & Technology

DOI: 10.1021/acs.est.2c01234 - Title: “Photocatalytic Nanomaterials in Healthcare: Tackling Antimicrobial Resistance”

Journal: ACS Applied Materials & Interfaces

DOI: 10.1021/acsami.3c00567