Ozone Sterilization Technology: A Powerful and Eco-Friendly Disinfection Solution

Ozone (O₃) is one of the most powerful oxidizing agents known to science, and its applications in sterilization and disinfection have gained significant attention in recent years. From healthcare and food safety to air purification and water treatment, ozone’s ability to eliminate harmful microorganisms and neutralize odors makes it a versatile and effective solution for various industries. In this article, we will explore the science behind ozone sterilization, its applications, advantages, limitations, and safety considerations.

Understanding Ozone Sterilization

Ozone (O₃) is a molecule composed of three oxygen atoms. It is a highly reactive gas that can break down into oxygen (O₂) in the presence of UV light or heat. Due to its strong oxidizing properties, ozone has the ability to destroy bacteria, viruses, fungi, molds, and other harmful microorganisms by disrupting their cell membranes and altering their cellular structure.

The process of ozone sterilization works through oxidation, a chemical reaction where ozone breaks down the molecular structure of pathogens. When ozone interacts with a microorganism, it oxidizes the cell membrane or the viral proteins, causing the microorganism to die or become inactive. The key advantage of ozone is its ability to perform this function without leaving harmful residues or requiring harsh chemicals.

How Ozone Sterilization Works

Ozone sterilization works by generating ozone gas (O₃) and exposing the target surface, water, or air to it. The most common methods for ozone generation include:

- Corona Discharge Method: This method generates ozone by applying a high-voltage electrical discharge to oxygen (O₂) in the air, causing it to split and recombine into ozone. This is the most widely used method for generating ozone in industrial and commercial applications.

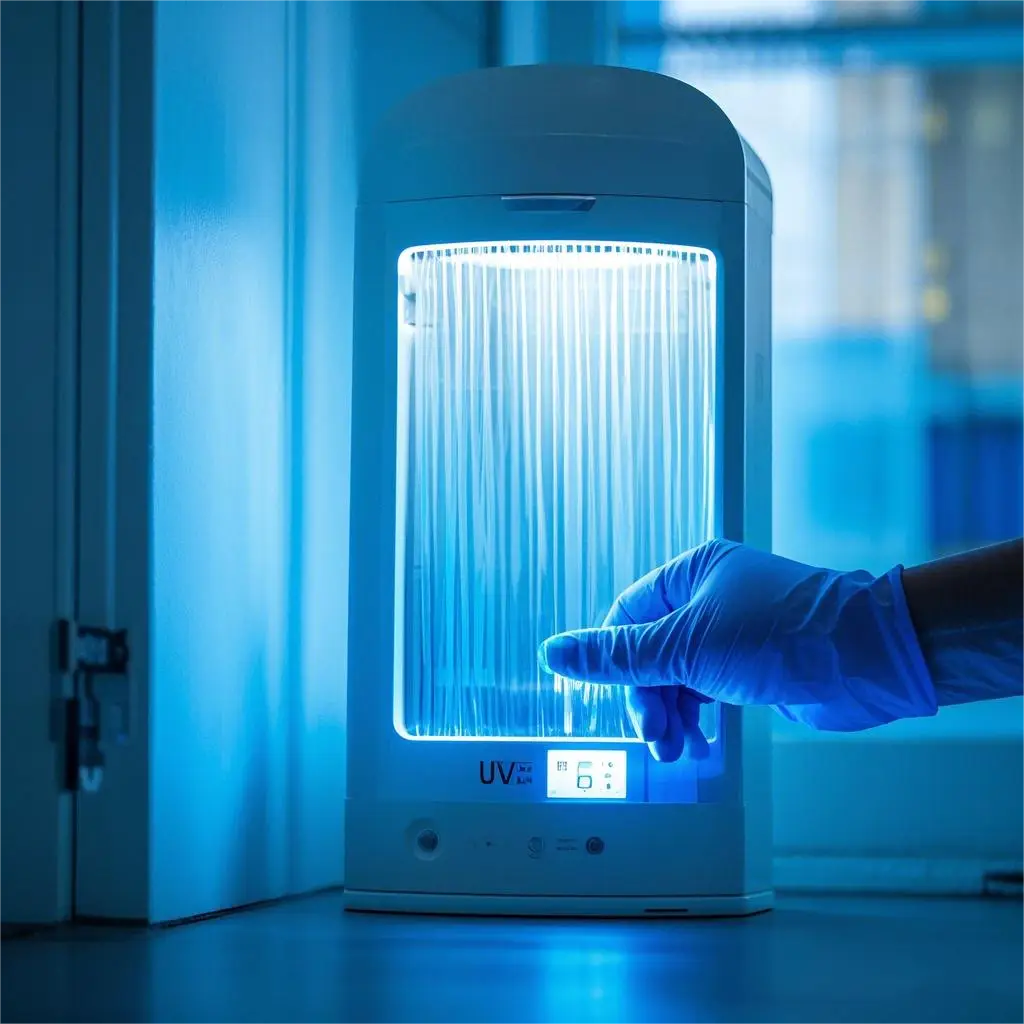

- UV Ozone Generation: When ultraviolet (UV) light interacts with oxygen molecules, it splits them and creates ozone. This method is typically used in smaller systems and for specific applications like water treatment.

Once ozone is generated, it is introduced into the environment to begin the sterilization process. The ozone molecules react with the microorganisms, oxidizing their cell membranes, nucleic acids (DNA or RNA), and proteins. The destruction of these critical cellular structures makes the microorganisms incapable of reproduction, effectively neutralizing them.

Applications of Ozone Sterilization

Ozone sterilization technology is versatile and is used across a wide range of industries, from healthcare to food safety and environmental management. Some of the primary applications of ozone include:

- Water Treatment

- Drinking Water Disinfection: Ozone is a highly effective disinfectant for drinking water. It neutralizes harmful pathogens such as bacteria, viruses, and protozoa, making water safe for consumption. Unlike chlorine, ozone does not leave harmful byproducts, making it an ideal choice for purifying potable water.

- Wastewater Treatment: Ozone is used in the treatment of wastewater to eliminate contaminants and improve the quality of water before it is released back into the environment. It is effective at breaking down organic compounds, killing pathogens, and reducing odor.

- Swimming Pool and Spa Disinfection: Ozone is used in pool and spa systems to disinfect the water. It effectively kills bacteria, viruses, and algae without the harsh chemicals found in traditional chlorine treatments.

- Air Purification

- Ozone is commonly used in air purifiers to eliminate airborne contaminants such as bacteria, viruses, and mold. It is also effective at neutralizing odors in spaces like hospitals, restaurants, hotels, and commercial buildings. Ozone air purifiers are especially beneficial in spaces that require high standards of hygiene, such as medical facilities and food processing plants.

- Deodorizing: Ozone’s ability to neutralize odors is a key advantage. It breaks down odor molecules at a molecular level, making it an excellent solution for removing odors caused by smoke, cooking, pets, and mildew in indoor environments.

- Food and Beverage Industry

- Surface Sterilization: Ozone is used to disinfect food processing equipment, surfaces, and storage areas, preventing contamination from harmful microorganisms and extending the shelf life of food products.

- Food Sanitization: Ozone is used to sanitize fruits, vegetables, meats, and seafood. By reducing microbial contamination, ozone helps improve the safety and quality of food products. It also helps preserve freshness and reduce the need for chemical preservatives.

- Medical and Healthcare Environments

- Sterilization of Medical Equipment: Ozone is used in medical settings to sterilize equipment that cannot tolerate high heat or chemicals. It is especially effective in disinfecting hard-to-reach surfaces and instruments like endoscopes, surgical tools, and implants.

- Room Disinfection: Ozone is utilized for room sterilization in healthcare settings to reduce the risk of hospital-acquired infections (HAIs). Ozone can be used to disinfect patient rooms, operating theaters, and laboratories by circulating the gas through the air and onto surfaces.

- Mold and Mildew Control

- Ozone’s oxidative properties make it highly effective at killing mold, mildew, and fungi. It is commonly used in mold remediation projects to disinfect affected areas and remove airborne spores. Ozone treatment can help eliminate persistent mold odors in homes, offices, and industrial settings.

- Industrial and Commercial Applications

- Ozone is used in a variety of industrial applications, including surface sterilization, equipment cleaning, and the disinfection of commercial spaces such as food packaging areas, pharmaceutical manufacturing plants, and warehouses.

Advantages of Ozone Sterilization

- High Effectiveness: Ozone is a powerful oxidizing agent that can destroy a broad spectrum of pathogens, including bacteria, viruses, fungi, and molds, without the use of harsh chemicals.

- No Residuals: Unlike chemical disinfectants, ozone does not leave harmful chemical residues behind. It decomposes into oxygen, making it a safe and eco-friendly solution for disinfection.

- Fast Acting: Ozone sterilization works quickly, often requiring only a short period of exposure to eliminate microorganisms. This makes it ideal for time-sensitive applications like water treatment and air purification.

- Versatility: Ozone is effective across a wide range of applications, from water and air disinfection to surface sterilization and food safety, making it a highly adaptable solution for various industries.

- Environmental Benefits: Ozone is a natural substance and does not contribute to environmental pollution when used properly. It also breaks down into oxygen, making it a safer and more sustainable option than other chemical disinfectants.

Limitations of Ozone Sterilization

- Toxicity at High Concentrations: While ozone is safe at low concentrations, exposure to high levels can be harmful to humans and animals. Prolonged exposure to ozone can cause respiratory problems, eye irritation, and damage to lung tissues. Therefore, ozone disinfection systems must be used with proper safety precautions to prevent human exposure.

- Short Half-Life: Ozone has a very short half-life and decomposes quickly into oxygen. This means that it must be generated and used in real-time, requiring specialized equipment and infrastructure.

- Limited Penetration: Ozone sterilization requires direct exposure to the target area. It may not be as effective in areas with poor air circulation or in porous materials that prevent ozone from reaching the microorganisms.

- Odor Issues: While ozone can effectively neutralize odors, improper use or over-concentration can leave behind a distinct, pungent ozone smell, which may linger in treated spaces.

Safety Considerations

When using ozone for sterilization, it is critical to follow safety guidelines to minimize exposure risks. Ozone generators should be operated in unoccupied spaces, or with proper ventilation systems in place to disperse the gas. Personal protective equipment (PPE), such as gloves, masks, and eye protection, should be used when handling high concentrations of ozone.

Conclusion

Ozone sterilization is a powerful, eco-friendly, and highly effective method for disinfecting air, water, surfaces, and food products. With its broad-spectrum efficacy, fast acting nature, and ability to leave no harmful residues, ozone is a versatile solution across a range of industries, including healthcare, water treatment, food safety, and air purification. However, ozone must be used with caution, adhering to safety standards to avoid potential toxicity risks. When applied correctly, ozone sterilization offers a safe, sustainable, and efficient way to eliminate harmful microorganisms and maintain high hygiene standards.