How to Disinfect Medical, Surgical and Dental Instruments After Use and the Technical Directions

Disinfection Methods for Used Medical Instruments

For Surgical Instruments

– Initial Cleaning: Immediately after surgery, rinse the instruments under warm running water to remove blood, fluids, and tissue. Do not process different metals together.

– Disinfection: Immerse the instruments completely in an EPA-approved disinfectant for about 10 minutes, and then rinse them with water again. Avoid using bleach or other corrosive chemicals.

– Thorough Cleaning:

– Soaking: Use an enzymatic cleaner bath or a solution of water and neutral pH (7) detergent. Instruments should be fully submerged for at least 10 minutes.

– Ultrasonic Cleaning: Most instrument manufacturers recommend ultrasonic cleaning as the most effective way to clean surgical instruments, especially those with hinges, locks, and other moving parts.

– Manual Cleaning: Use stiff nylon cleaning brushes. Use only neutral pH detergents.

– Sterilization (Autoclaving): Follow the sterilizer manufacturer’s written instructions for cycle parameters. The common temperatures and time parameters are 10 to 25-minute exposure time at 132 ° to 135 °C (270 ° to 275 °F) or 15 to 30-minute exposure time at 121 ° to 123 °C (250 ° to 254 °F).

For Dental Instruments

– Preliminary Treatment: Use normal saline or water to initially rinse the instruments to remove surface dirt. Then, soak the instruments in an enzyme-containing cleaning agent. The soaking time should be controlled according to the product instructions. Finally, use a special brush to scrub the instruments to ensure that each part is cleaned thoroughly.

– Disinfection Treatment:

– Drying: Place the cleaned instruments on a drying rack and dry them naturally or with a dryer.

– Disinfectant Selection: Select an appropriate disinfectant according to the material of the instrument, such as chlorhexidine, hydrogen peroxide, etc.

– Immersion Disinfection: Completely immerse the instruments in the disinfectant. The immersion time should follow the instructions of the disinfectant.

– Rinsing: After disinfection, rinse the instruments with sterile water to remove the residual disinfectant.

– Packaging and Sterilization: Use sterile packaging materials, such as medical paper or sterile bags. Then, use a high-pressure steam sterilizer to sterilize the instruments. The temperature and time should be adjusted according to the type of instrument.

Technical Directions

– Intelligent Disinfection Monitoring: Utilize sensors and the Internet of Things to monitor disinfection parameters in real-time, ensuring disinfection standards are met and enabling automatic recording and traceability.

– Green and Environmentally Friendly Disinfection Technology: Develop disinfectants that are more environmentally friendly and less corrosive, reducing harmful chemical emissions and residues during disinfection.

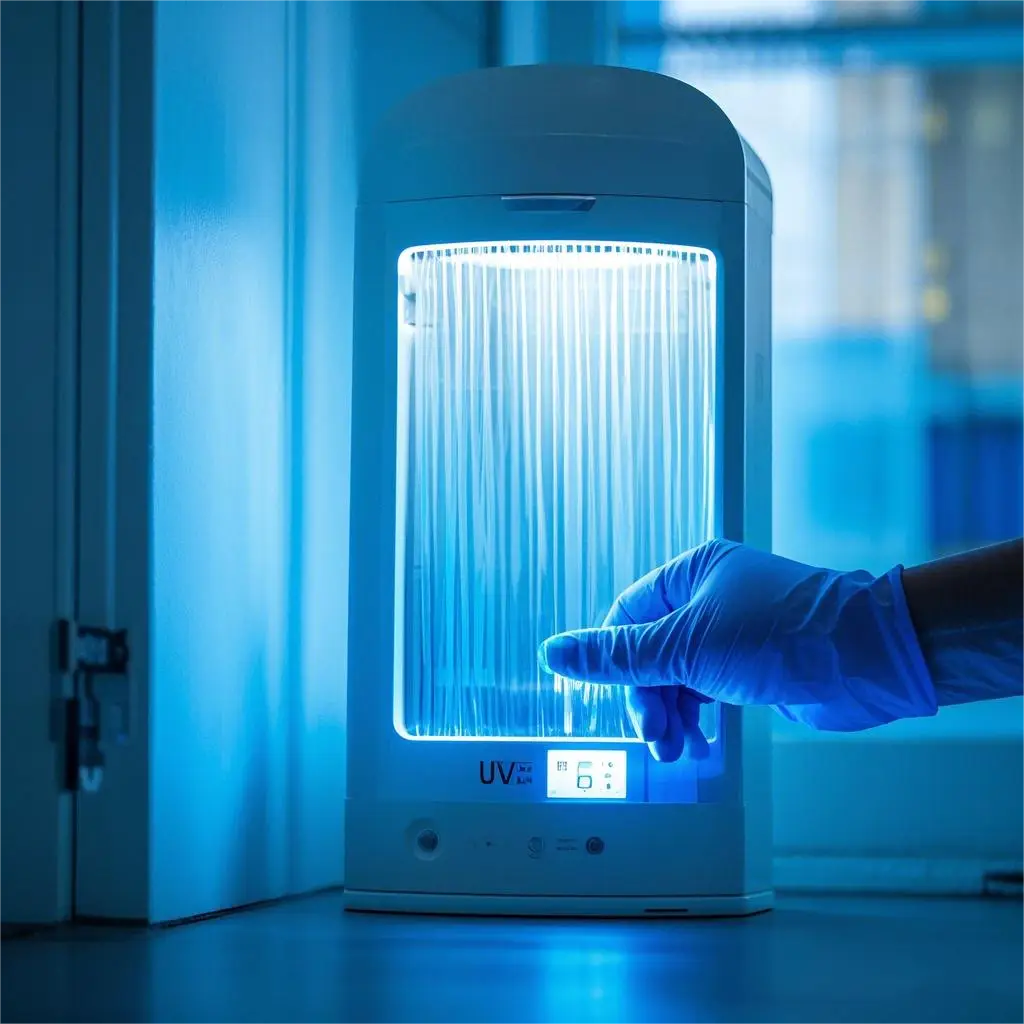

– Efficient and Rapid Disinfection Technology: For example, develop new plasma generation devices to further shorten the disinfection time and improve the turnover efficiency of instruments.

– Multifunctional Integrated Disinfection Equipment: Integrate multiple disinfection methods into one device, which can automatically select the appropriate disinfection mode based on the material and type of the instrument.