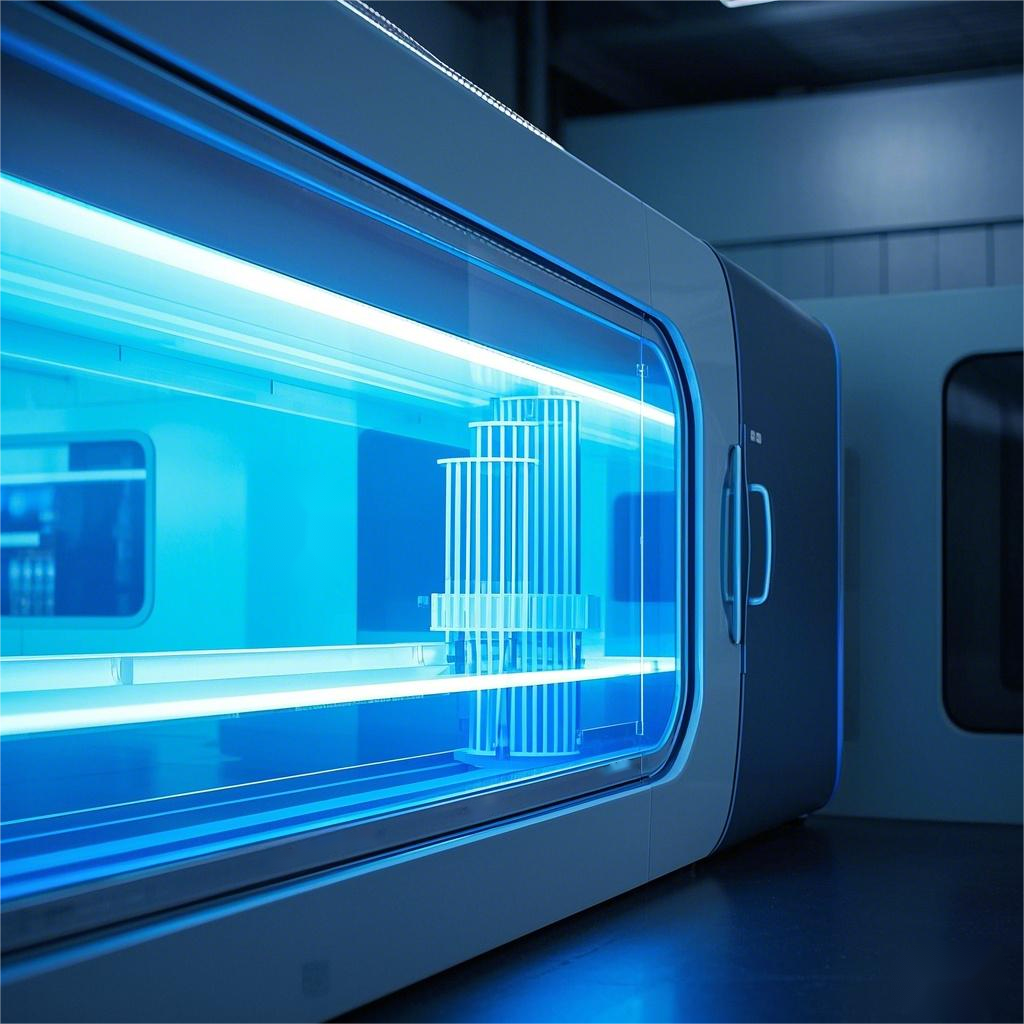

As a global leader in disinfection solutions, Nanjing Legia Smart Technology Co., Ltd. combines state-of-the-art sterilization tech to redefine safety standards across residential, commercial, and medical sectors. This deep dive explores how Legia’s award-winning product portfolio leverages innovative science—from UV-C and ozone to IoT-driven precision—to deliver 99.99% pathogen elimination and compliance with international regulations.

1. Multi-Modal Sterilization Synergy

Legia’s systems combine three WHO-recognized sterilization methods:

- UV-C Light Technology: High-intensity 253.7nm ultraviolet lamps disrupt microbial DNA/RNA structures, achieving 99.99% pathogen elimination.

- Ozone (O₃) Disinfection: Patented ozone generators produce 360° gas diffusion, penetrating complex surfaces and neutralizing odor-causing bacteria.

- Thermal Sterilization: Precision-controlled heating modules (125-135°C) ensure spore destruction for medical-grade compliance.

2. Intelligent Control Systems

Embedded with industrial-grade PLCs and IoT sensors, Legia’s cabinets feature:

- Real-time temperature/humidity monitoring

- Automatic cycle adjustment based on load detection

- Safety interlocks preventing ozone/UV leakage

- Energy optimization algorithms reducing power consumption by 30%

3. Material Innovation

Medical-grade 304 stainless steel chambers with nano-ceramic coatings resist corrosion while enabling easier cleaning. UV-resistant polymer seals maintain 10-year structural integrity even in high-humidity environments.

4. Compliance-Driven Design

All medical-grade units comply with:

- EN 60601-1 (Medical Electrical Equipment Safety)

- ISO 15883 (Washer-Disinfectors)

- FDA 510(k) standards for critical device reprocessing

5. Customizable Solutions

Legia’s R&D team tailors sterilization parameters for specialized applications:

- Low-temperature cycles for delicate fabrics (55°C)

- Pulsed ozone delivery for food service compliance

- Dual-wavelength UV (265nm+285nm) for multi-drug resistant organisms

Keywords:Advanced Sterilization Technologies/UV-C Disinfection Systems/Ozone Sterilization Solutions/Thermal Disinfection Technology/Medical-Grade Sterilization/

WHO-Recognized Disinfection/FDA-Compliant Sterilization/IoT-Enabled Disinfection Cabinets/Hospital Disinfection Equipment/Multi-Modal Pathogen Elimination